How to operate the mask?

1. Prepare a towel, terming bed, and the right mask. Adjust the water bath to 65-70℃.

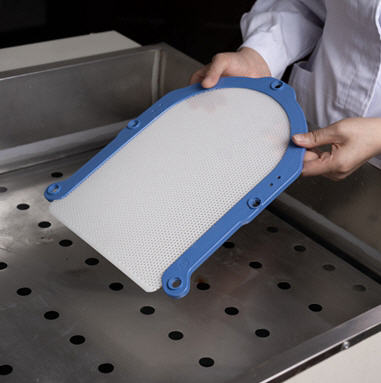

2. Sink the radiotherapy mask into hot water for 2-3 minutes, it could become soft and pliable.

3. Put the mask on the towel, wrap its water.

4. Put the thermoplastic mask on the patient's body part, mould it with fingers to the right position. It offers 2-3minutes to fulfill the task.

5. As the temperature drops, the mask could become harder and harder, and keep the moulding style well.

6. After 24 hours, the mask could reach to an ideal rigidity, thus to play a role of immobilization and positioning during cancer treatment.

Moulding a Radiotherapy Mask 6 things often go wrong but can easily be avoided

1. Adjust the water temperature to 68℃-72 ℃ , more than 80 ℃ will make the mask contraction and deformation.

2. Be sure not to place the mask in hot water for a long time. In general, 2-3 minutes should be enough to make the mask soften and activation.

3. The available time for modeling the mask is 3 ‘30 ‘’(3 minutes and 30 seconds)

4. The maximum tensile strength of orthopedic sheet is 1.5 times of its original size; And the maximum tensile strength of the mask product is 6 times of its own. Excessive pulling could affect its reshaped resilience and damage its memory function.

5. How to restore a molding mask back to its factory settings? Just put it into the 68℃-72℃ water and then it will rebound automatically after 5 minutes.

6. Due to the characteristics of the material itself, in the activation process, it will occasionally occur small area of sticky. Please be sure not to pull randomly. When it leaves the water to solidify, it will automatically relieves adhesion.